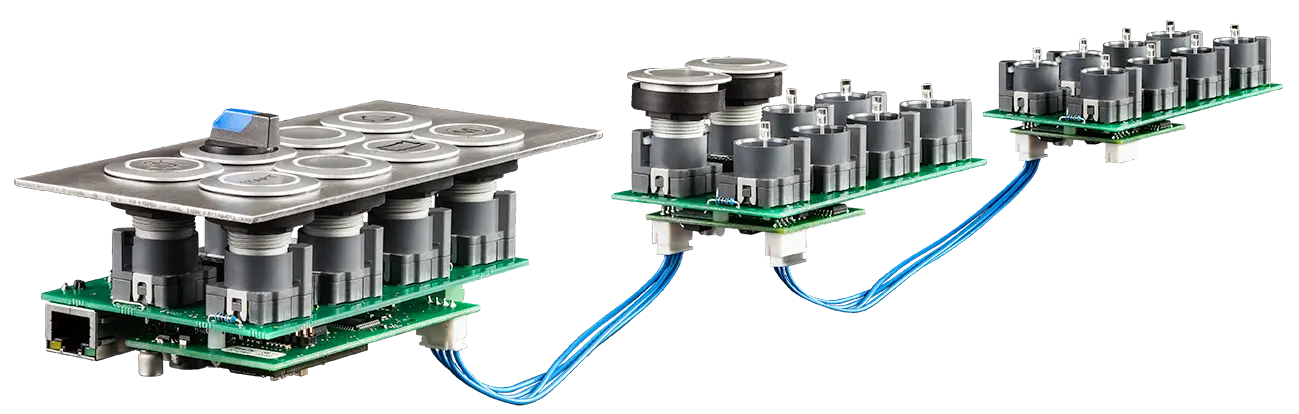

THESE ARE THE CHARATCTERISTICS OF THE SCHLEGEL MODULAR SYSTEM:

Direct integration of pushbuttons, pilot lights and switches in industrial networks

Only one connection for up to 128 pushbuttons, pilot lights and switches

Basic module can be extended by up to 15 bus independent I/O modules

Minimum wiring effort, saving time and money

Higher flexibility: individual adaption by customised modules

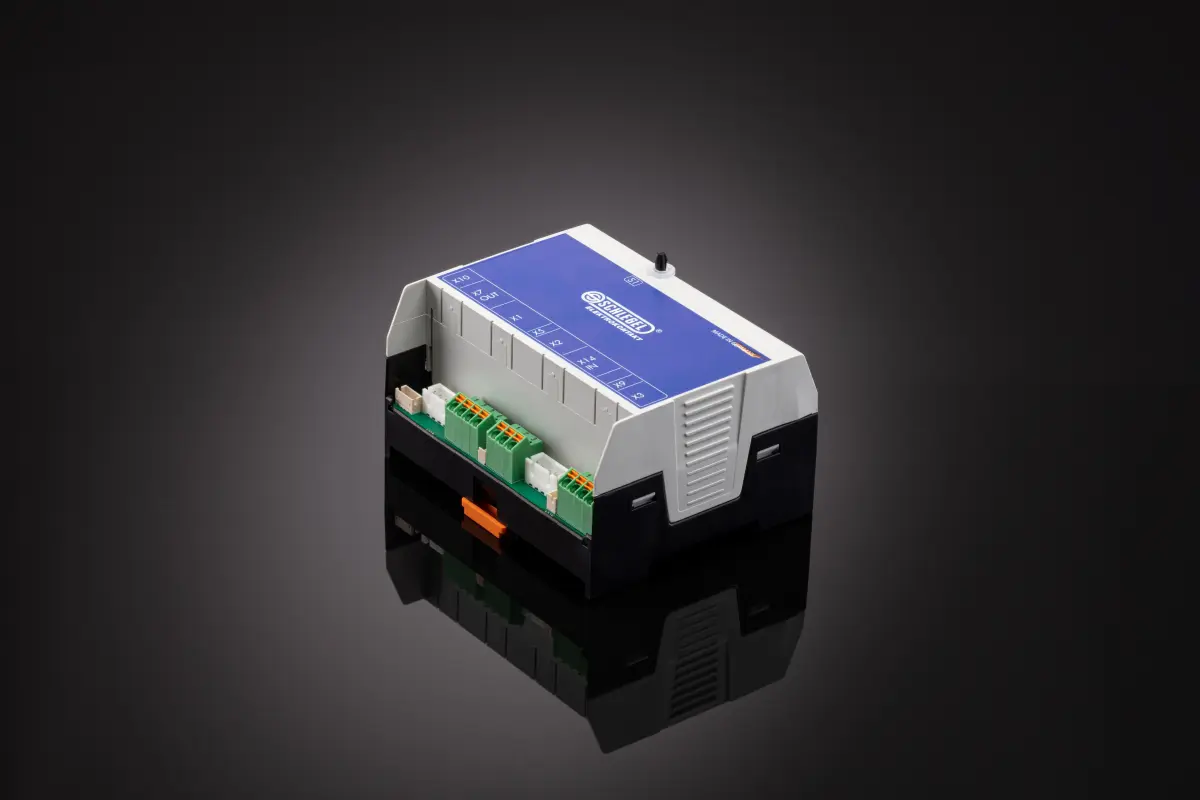

Easy and cost-effective change of the bus system by exchanging the basic module

SCHLEGEL offers standardised modules suitable to the individual series in a grid of 25 x 25 mm / 27 x 27 mm / 30 x 30 mm

No rigid system: if the requirements change, the MBS can be expanded at any time

Versatile: thanks to its structure, the MBS is suitable for many fields of application

FAQ

What is a fieldbus system?

In this system, sensors and actuators are connected with each other via a bus on a field level. The sensors and actuators are placed on power units, switches and control elements (transmitter) and exchange data with the control devices (receiver) via the bus system. The control devices then activate the corresponding function.

What is Industrial Ethernet?

Industrial Ethernet is the expansion of Ethernet by the ability of real-time functionality as it is already the case for fieldbus systems. As Ethernet components don´t need a fix address, an Industrial Ethernet can be expanded easier and faster.

What is the difference between fieldbus and Industrial Ethernet?

The most significant difference lies in the level on the automation pyramid into which those systems fall. Fieldbus systems are part of the lower levels "field and sensor/actuator", whereas Industrial Ethernet is present on all of the levels. The benefit is that the communication through all levels is much easier.

Which systems are preferred in the industry?

Which systems are preferred in the industry? The most used fieldbus systems are Profibus, Modbus-RTU, CC-Link and CANopen. For the Industrial Ethernet, they are EtherNET/IP, Profinet, EtherCAT and Modbus-TCP.