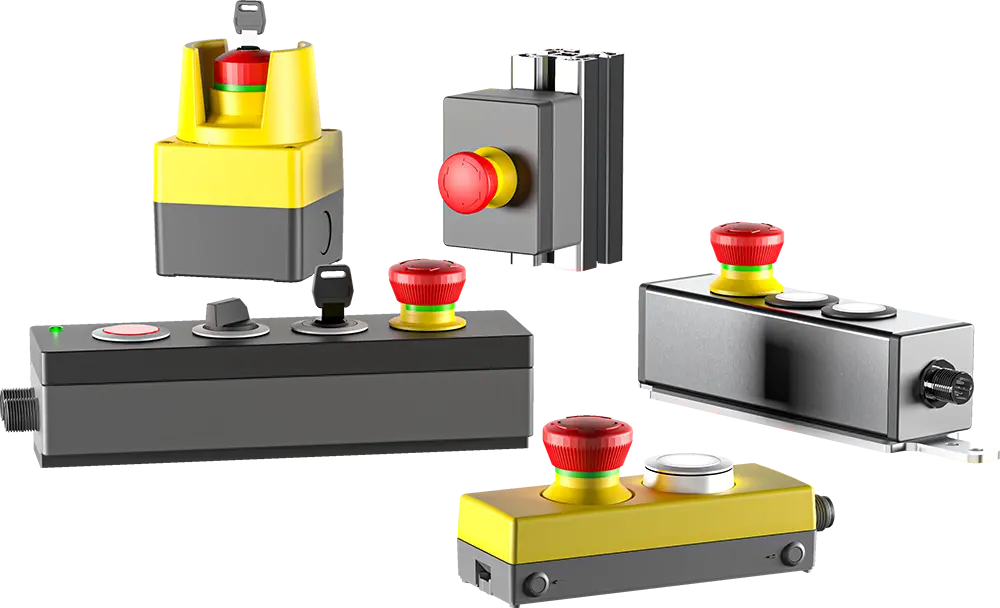

EMERGENCY-STOP SWITCHES WITH ILLUMINATED STATUS INDICATION ACTIVE/INACTIVE

SELF-MONITORING EMERGENCY-STOP CONTACT BLOCKS

The self-monitoring emergency-stop contact blocks developed by SCHLEGEL increase the safety. The functional principle: In case of a negligent assembly or a mechanical damage (separation of contact block from the actuator) the self-monitoring emergency-stop contact block ensures the immediate automatic activation of the emergency-off signal. The installation is switched off and can only be restarted after successful trouble-shooting.

Safety@Work

Safety@Work allows you to expand existing AS-Interface systems by emergency-stop switches and other safety-related components. Please ask our sales staff about the significant advantages – we will be glad to advise you!

Enclosure-mounted emergency-stop and reset button

Difference between emergency-stop and emergency switch-off

THESE ARE THE FEATURES OF SCHLEGEL EMERGENCY-STOP SWITCHES

UL and TÜV approval

Panel cut-outs: Ø 16.2 mm, Ø 22.3 mm, Ø 30.5 mm as well as 23 x 23 mm, 24 x 24 mm, 26 x 26 mm

Clearly visible switching position indicator

Twist to release (in both directions) or release by pulling

Degree of protection is IP65 to IP69K, depending on the type

Certified acc. to the standards EN 60947-5-5 and DIN EN 13850

Contact blocks with positive opening acc. to EN 60947-5-1, appendix K, one or two-channel versions are available

Even low currents (5 mA at 24 V or less) can be switched reliably

Standard contact blocks as well as AS-Interface (Safety@ Work) contact blocks are available

FAQ

What is an emergency-stop button?

An emergency-stop button is a switch that puts a machine or a plant in a safe state in the event of danger. The emergency-stop button is locked after being actuated and the corresponding part of the machine or plant is shut down. Only after releasing the emergency-stop button the system can be started again.

What is an emergency shut-off button?

An emergency shut-off button is a switch through which machines or plants are cut off from the power supply in the event of danger. In contrast to an emergency-stop button the machine or plant is not being put in a safe state first, so the machine or plant can still pose a danger.

Which standards to be observed regarding emergency-stop buttons?

The machinery directive (2006/42/EG) requires for all machines to be equipped with at least one emergency-stop button. To ensure that an emergency-stop button can fulfil the requirements for a safe operation, it should be in accordance with the standards EN 60947-5-1, EN 60947-5-5 and DIN EN ISO 13850 and be tested according to TÜV or VDE.

What is a start-stop button?

A start-stop button has a similar operating principle as an emergency-stop button. Here the button will be locked as well after being actuated and can only be released by twisting or pulling. However, a start-stop button must not be used in a safety-relevant environment and thus may not have red/yellow colours.

What is a mushroom head?

A mushroom head has a similar design to an emergency-stop or start-stop button. In contrast to those buttons however, the mushroom head does not latch and only triggers a brief impulse. Mushroom heads are meant to be actuated quickly and safely, but they must not have the signal colours of red/yellow.