individual

fast

cost-optimised

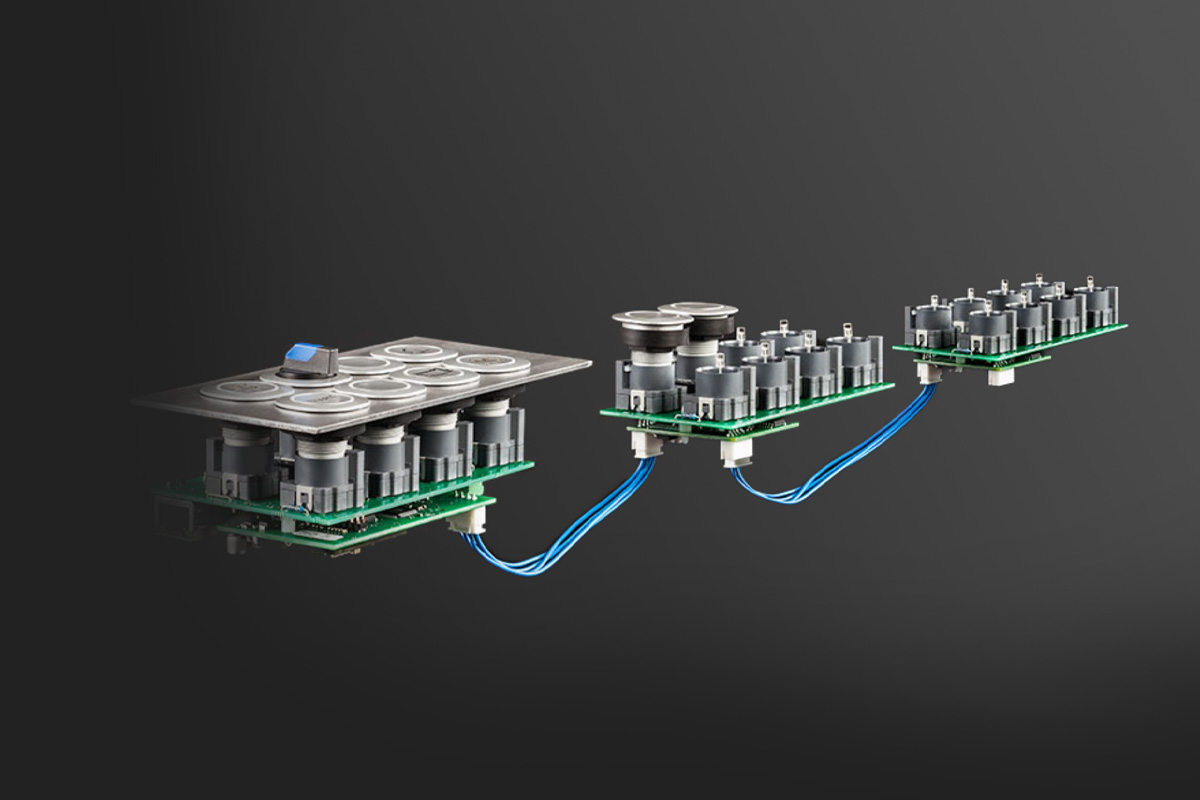

If your design plans cannot be implemented with the standardised modules, we can respond to your special design requirements anyway. For customised designs we resort to sub-modules of the modular concept by adapting only the carrier board with the command points (PCB with individual contact blocks) according to your design proposal, consequently, the cost-optimised solution also taking effect here.