What is an emergency switch-off?

- Switching off of a conveyor plant due to collision.

- Switching off an electrical device due to overload or short circuit.

Safety function: Immediate switch-off of the power supply to a machine or plant.

Application: Dangerous situations that bear the risk of electrical shocks or a risk of another electrical origin.

Technical realisation: Disruption of the electric circuit so that the power supply is stopped.

What is an emergency-stop?

An emergency-stop, also known as emergency-stop button, pursues another target. Instead of completely disrupting the power supply, the operation of the machine is put in a safe mode in which all movements that pose a risk are immediately stopped.

The machine or plant is being stopped uncontrolled by distrupting the power supply. To do this, the motor is being disconnected from the power and either comes to a halt slowly and uncontrolled or is being stopped by a mechanical brake.

The machine or plant is being stopped controlled and the power supply remains active to brake movements electrically. After the moving part comes to a halt, the power supply is being cut off.

A machine or plant is being stopped controlled, however the power supply to the driving element stays active. The motor is being slowed down electrically and remains in speed or position control mode. This category may not be used to switch off machines or plants in case of danger.

- Emergency-stop of a robot to prevent injuries while the power supply for diagnosis remains active.

- Shutdown of a production line to correct a mistake without stopping the process completely.

Safety function: The machine movement is being stopped controlled and depending on the stop category the power supply remains.

Application: Processes that require a controlled stop.

Technical realisation: Quick stop of dangerous movements of the machine or plant, followed by a disconnection of the power supply.

Significance of the right choice of switch

Why is the differentiation so important?

Conclusion: emergency switch-off and emergency-stop – two systems with the same goal

While the emergency switch-off convinces with a complete disruption of power supply, the emergency-stop ensures a safe stopping of the machine without loss of power supply. Both systems play a decisive role for machine safety and should be carefully adjusted to each application.

FAQs

What is the main difference between emergency switch-off and emergency-stop?

The emergency switch off cuts off the power supply whereas activating an emergency-stop will put a machine or plant in safe mode.

When should an emergency switch-off button be used?

In every situation that requires immediate shutdown to prevent greater danger.

Is an emergency-stop required by law?

Yes, according to the regulations regarding machine safety, each machine has to be equipped with corresponding safety functions.

Can an emergency-stop also be used as an emergency switch-off?

Yes, the difference only applies to the definition of use. In general, a pushbutton or switch that complies with the criteria of the norms DIN EN ISO 13850 and DIN EN 60204 can be used either as an emergency switch-off or an emergency-stop.

Which regulations control the application of emergency switch-off and emergency-stop buttons?

The application of emergency switch-off and emergency-stop systems is controlled by the norm DIN EN ISO 13850 as well as the machinery regulation 2006/42/EG. Those determine that each machine must be equipped with appropriate safety devices to be able to stop the operation safely or disrupt the power supply in case of emergency.

Can an emergency switch-off be reset?

Yes, an emergency-switch off can be reset after the dangerous situation is resolved. In most cases, the button is twisted, pulled or released with a key to do so. It is important, though, that the reset will not automatically get the machine running again.

Where do emergency switch-off and emergency-stop buttons have to be positioned?

Emergency switch-off and emergency-stop buttons should be mounted somewhere easily accessible to ensure they can be reached without any problems in case of emergency. Most common places for them are control panels, work stations or directly on the machine, ideally in line of sight and range of the operator.

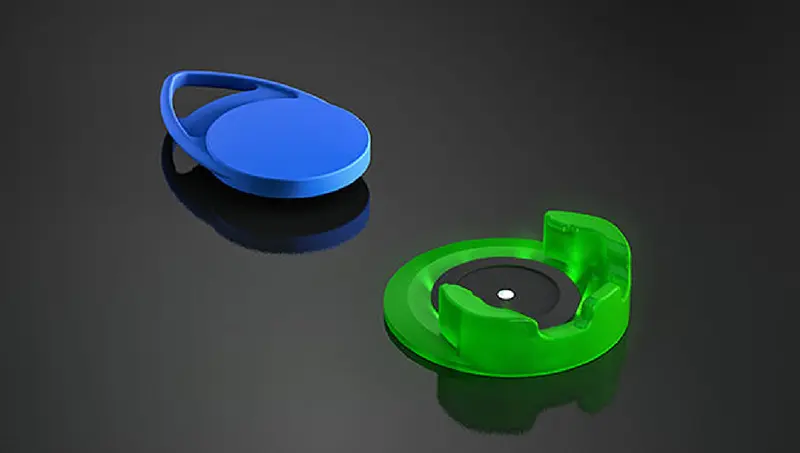

Which colours and symbols signify emergency-stop buttons?

According to the norm DIN EN ISO 13850, an emergency-stop has to be a red operating unit with a yellow housing or background to make sure it can be identified quickly in emergency situations.