How so?

Conventional displays are rectangular, the reason for that being the implemented Chip On Glass technology where the electronics is installed on the display´s glass. Due to the space needed for this technology, a square display shape is – at least if it should offer an acceptable edge width – not feasible. For Flexitast however, the Chip On Flex technology is being used. Here, the electronics is placed on a Flex cable. Thanks to this, the edge can be kept symmetrically narrow and a square display is possible. Therefore, the search for a partner who can develop such a display for SCHLEGEL was not that easy. But all good things are worth waiting for: With the Actron AG, we have found a suitable partner for the successful development of the Flexitast.

Is the Flexitast only intended as a solution for panels?

There are various versions: The Flexitast as a single button which is monitored and controlled via an external system or as a system where up to 30 buttons can be connected with each other. Its full capability is shown in the system solution which enables high scalability for complex control requirements and thus is especially useful for bigger control systems. The Flexitast buttons communicate via a gateway, acting between the button system and the external system. They are monitored and controlled by an external system, for example a PLC or IPC.

All Flexitast buttons are connected to each other via a cable. With a maximum cable length of 30 meters and a distance between each button of up to 5 meters, the Flexitast system can be flexibly implemented in various environments.

Furthermore, the Flexitast offers the possibility of individual modification according to customer´s wishes. Additional functions and interfaces can be implemented which makes the integration in existing systems and specific applications easier.

How can the pushbuttons be configured?

Simply use a web browser: Symbols, colours and the dimming can individually be set there. Customers can not only use preset standard symbols from SCHLEGEL, but also upload their own symbols and activate them, making the Flexitast a highly adjustable and versatile solution for control processes. This flexibility is important, especially when considering the environment in which customised or language-specific controls and displays are required, be it in the machine building industry, the building technology or other industrial fields.

What are the technical requirements?

There are no specific technial requirements for the Flexitast. Thanks to its robust design, it is also suitable for rough working conditions. Its degree of protection is IP65 and due to the protective glass cover on the display it is protected against wear and damage. Due to the display´s technology, there is no burn-in of the display, significantly increasing the lifetime. Thus, the Flexitast can perform 1 million switching cycles. The operating temperature ranges from -10°C to 50°C, the operating travel is 3 mm and the contact block is tactile with 2 NO contacts. The Flexitast is operated with an operating voltage of 24 V. The lifetime of the display is at least 10 years.

As the Flexitast can be configured variably and covers many applications, using many products becomes unnecessary. This saves time and costs in procurement and storage because only one product is necessary for various applications. Also, conventional PET nameplates are no longer needed which reduces the cost of materials.

For which applications do you see the benefit of Flexitast compared to "conventional" pushbuttons for the customer?

Due to its flexibility, robustness and adaptability, the Flexitast can be used for various applications. The button provides a benefit in all areas that require dynamic, visual controls, display of operating states regarding runtime or individual possibilities to adapt. I will gladly list some examples:

- In industrial control systems, the Flexitast offers an efficient possibility to visually monitor machines and plants and also control them. With the flexible modification of symbols and colours, processes can be controlled and changes in the switching state are displayed immediately.

- In the machine building industry, where precise control and monitoring of status are necessary, the Flexitast offers a visual feedback about a machine´s status.

- Machines that are shipped to different countries can easilly and quickly be adjusted to another language.

What do you think about the future development?

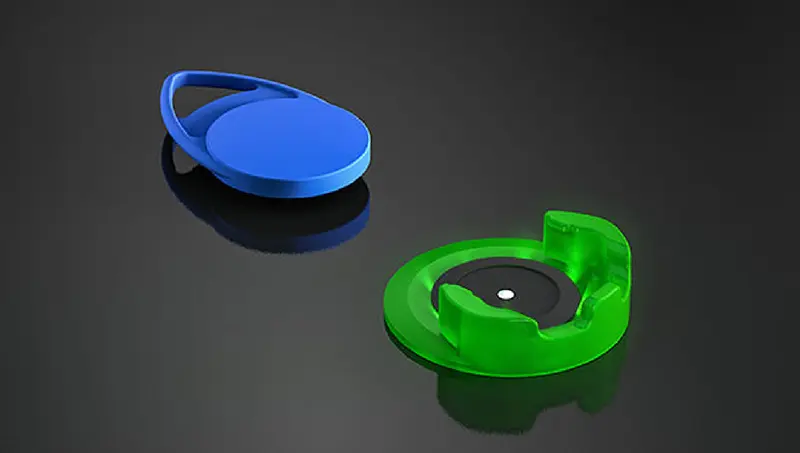

The Flexitast is an innovative milestone. It enables us to walk a new, innovative path with our pushbuttons, but the benefits and potentials of this system is far from being exhausted yet. The flexibly constructed system offers many more possibilities for customised applications and expansion. Furthermore, more variants are in the pipeline: From a bigger visible surface to a higher resolution and a round display.